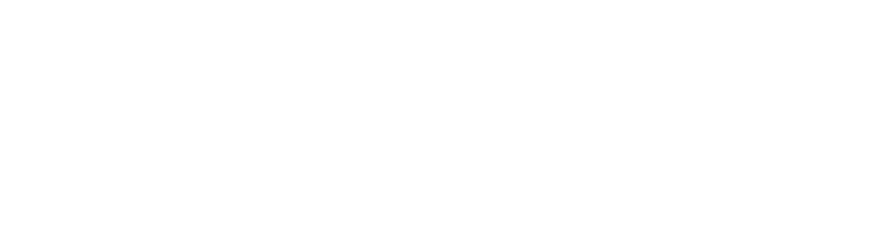

We’re pleased to share that we are currently building a new small batch brewery.

Our existing pilot brewery will continue to be used to run test batches for new recipes, but to share our beers and to keep up with demand we have invested in a larger brewing system.

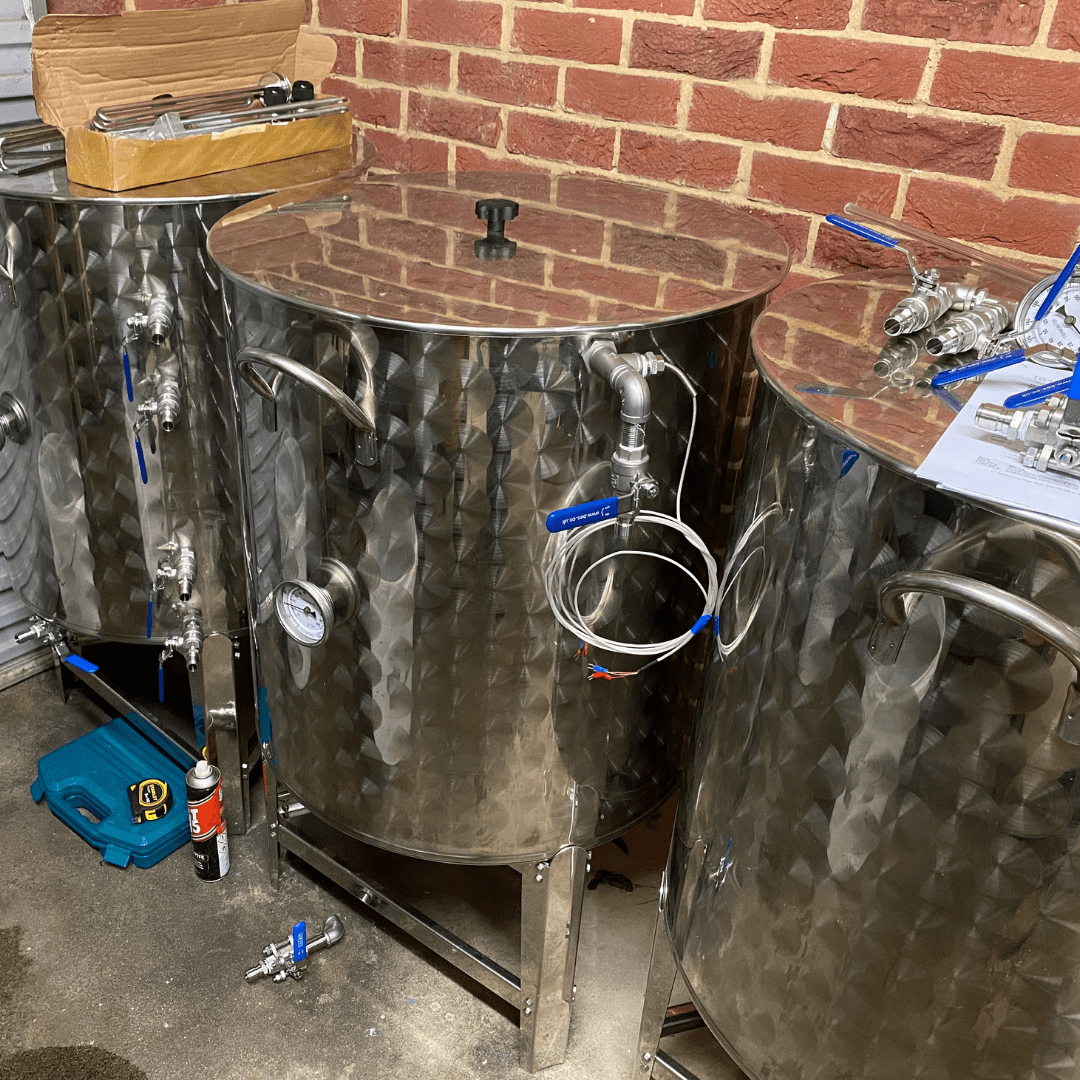

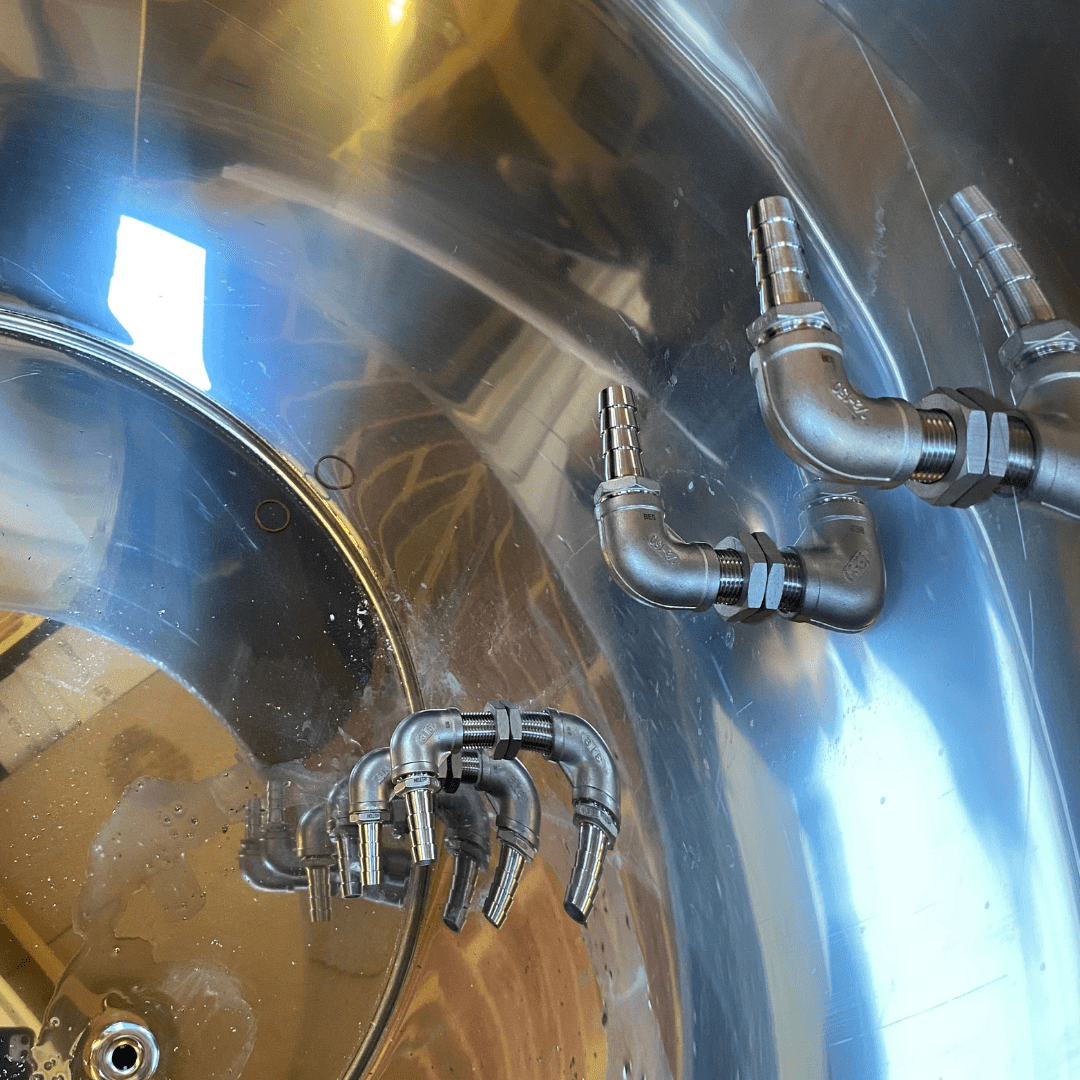

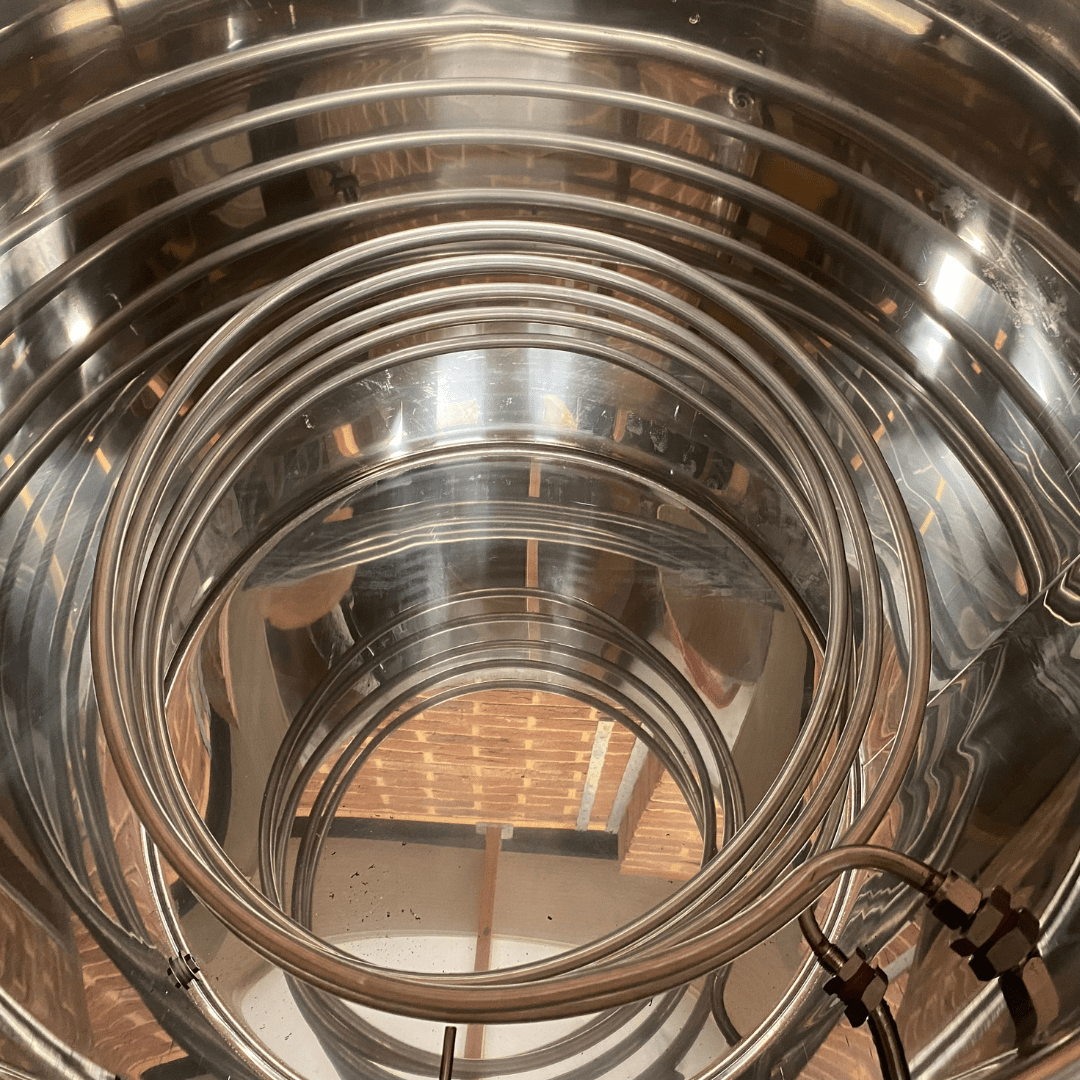

We’re passionate about hand crafting our beers, and the same goes for our brewing equipment- our new stainless steel vessels are being converted by Sam (when he’s not busy brewing of course).

Our new brewery will have an output of around 160 litres (or 1bbl), and comprises of a traditional three vessel system (Hot Liquor Tun, Mash Tun and Boil Kettle) whilst utilising a HERMS coil (heat exchanged recirculating mash system).

Update – April 2022

Our brewery build is finally finished after several weeks of drilling, wiring and generally not having a social life.

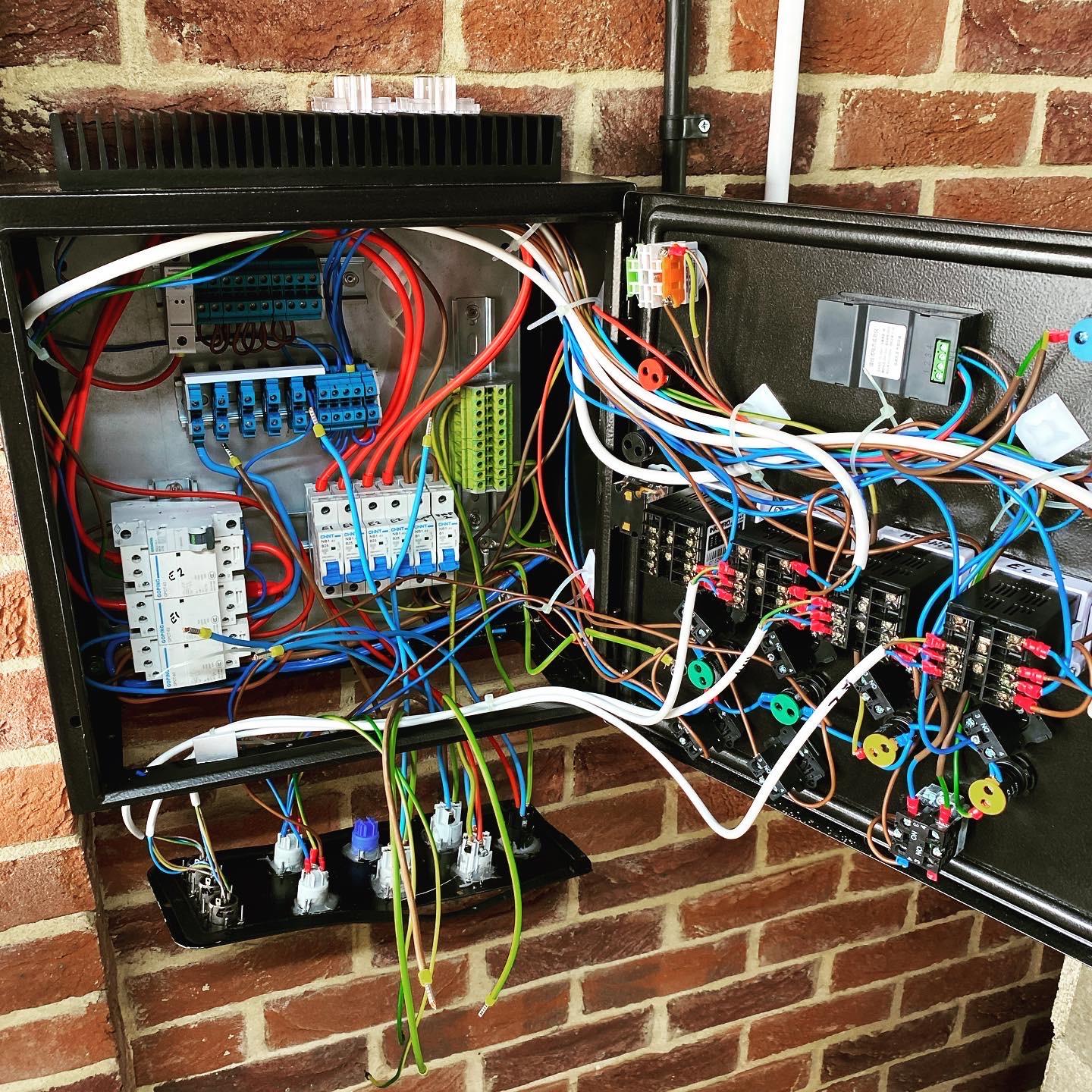

The final piece in the puzzle was to have a way of controlling our two 5.5kw heating elements in a precise way. These elements are overkill for the current size of the brewery, but with scalability in mind, Sam wanted to build a system that can easily grow with our brewery over the next couple of years.

The panel started life as a project back in 2020, when Sam built the enclosure. He was inspired by the Electric Brewery website which explains how to build your own brewery control panel. At the time, he intended it to run a home-brew sized system, but with our commercial brewing venture, it became the perfect way to run our 1 barrel pilot system.

We needed a dedicated power supply put into our outbuilding as our elements draw about 47 amps and would overheat our existing single phase wiring. After two solid days of wiring, the panel was tested and put to use!

2024 Update

We’ve had an amazing couple of years since we launched Datum Attitude. It’s truly humbling to look back at this blog to see how far we’ve come.

Our brewery can now produce up to around 4bbl or 600 litres per batch, using two stunning DPVs that we bought from our friends at a renowned London craft brewery.

Our smaller 1bbl pilot kit is still used for exciting new beers (in fact we kicked off 2024 by brewing a delicious imperial stout in one of the smaller tanks), and we cant wait to see what the future brings for Datum this year!

Stay tuned, and subscribe to our newsletter!